Pendeteksian cacat kualitas produk merupakan hal yang krusial untuk menghindari ketidakpuasan pelanggan, atau bahkan kerusakan dalam lini produksi. Untuk menjamin standar kualitas yang konsisten, kami sebelumnya terus-menerus melakukan inspeksi manual. Dalam kasus tertentu, bahkan dilakukan 100% pengecekan dan bukan hanya sampling secara acak untuk memenuhi kesepakatan kualitas dengan pelanggan.

Tantangan yang Kami Hadapi

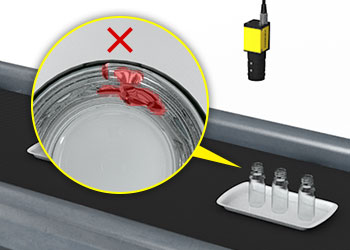

Dalam produksi, terdapat ketidakwajaran yang masih dapat diterima, namun ada juga yang harus dipisahkan. Mengirimkan bahan pengemas dengan cacat pada permukaan atau dekorasinya dapat berujung pada komplain dan penolakan, dimana kejadian tersebut bertentangan dengan komitmen kami untuk menghadirkan produk berkualitas kepada pelanggan. Terlebih lagi, cacat tampilan seperti debu, bintik, cacat printing, flashing, baret, dan lainnya merupakan jenis cacat yang terkadang sulit terdeteksi. Kesulitan tersebut mau tidak mau membutuhkan usaha yang menyedot tenaga dan waktu besar yang mengurangi efisiensi.

Inspeksi berbasis AI Biasa Tidaklah Cukup

Teknologi AI dan penglihatan mesin dapat menolong mengontrol kualitas secara efektif. Skenario dasar dan umum adalah sebuah perangkat foto menangkap gambar dari area permukaan kemasan dan mendeteksi tanda-tanda anomali berdasarkan kumpulan data yang menjadi acuan. Meskipun demikian, salah satu tantangan terbesarnya ketika berurusan dengan cacat permukaan/dekorasi pada bahan pengemas adalah sifatnya yang dinamis. Jenis cacat seperti baret atau noda bisa saja sulit dibedakan pada awal tahap produksi. Jenis cacat ini baru terlihat pada kondisi pencahayaan tertentu. Sementara cacat yang ditemukan pada akhir tahap produksi berarti biaya yang semakin tinggi.

Teknologi pendeteksi konvensional biasanya tidak mampu melihat jenis cacat permukaan yang kompleks seperti gelembung di dalam botol kaca, degradasi warna, baret, retak, dan isu lain. Jenis cacat seperti ini mudah dideteksi mata manusia, namun sulit diprogram oleh teknologi konvensional.

Kami Berinvestasi pada Teknologi Deep-Learning

Kami di Dermapack memutuskan mengembangkan teknologi AI, dan secara spesifik dalam Deep Learning Image Analysis untuk dapat secara lebih mendalam mendeteksi kecacatan pada permukaan kasar, mengkilap, matte, dan bertekstur pada plastik/kaca sehandal inspeksi manusia, namun secepat sistem komputer. Alat pendeteksian kecacatan dapat menangkap cacat dengan pencahayaan standar, bahkan dengan kualitas gambar yang buruk, dengan membangun model yang handal berdasarkan referensi gambar yang menjadi acuan. Lebih jauh lagi, dengan teknologi ini, kami hanya diharuskan melatih algoritma dengan sampel yang sedikit (50-100 pcs).